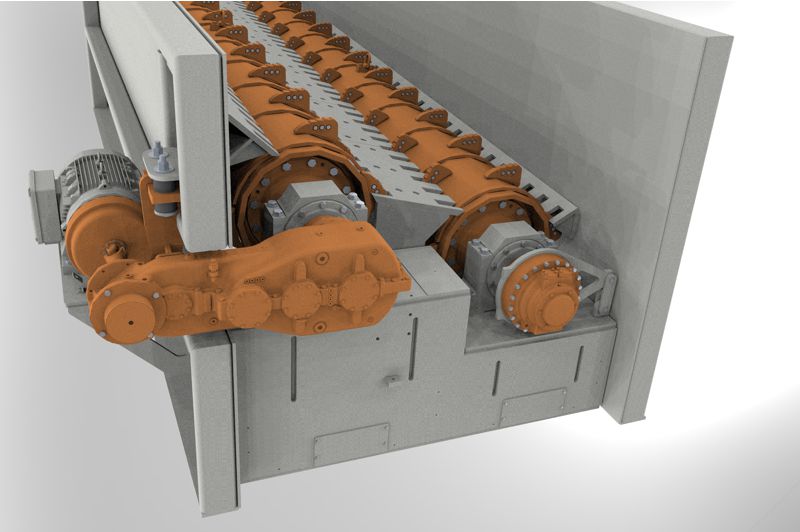

High capacity system with Rotary Debarker and Disc chipper

Turnkey solutions for debarker and chipper lines

High-class products as MDF plates or HDF plates require high-quality chips as base product.For its production, debarker as well as disc chipper are main factors. In order to make the most of both machine capacities, they need to be integrated in intelligent and reliable conveying systems.

HOLTEC offers high-class solutions for capacity ranges of 50 – 130 tons of chips (b.d. / h).

Rotary Debarker

In terms of the debarker we rely on the Rotary principle. The vario-barker developed by HOLTEC has been sold 15 times within 5 years. It could convince as unique machine on the market by having the possibility to adjust the machine inclination hydraulically. By doing so the debarker and therewith the debarking result can be adjusted perfectly well to the log quality and nature.

Disc chipper

For MDF we clearly favour the disc chipper technology, providing an optimal chip geometry and a low amount of fines. Together with our partner we offer solutions with 2,800 – 4,000 mm disc diameter and drive capacities of up to 2,000 kW.

We understand our role as partner for the complete process – from the log infeed up to the chip discharge. Our concepts are based on a detailed analysis of the whole processes and are completed by an overall engineering – without any interface for the operator.

News from the Wood-based panel industry

What can we do for you?

Write us a message. We will get back to you as soon as possible.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/746272f8c7.jpg)