Rotary Debarker: Electric drive as economic alternative to hydraulic motor

Main reason for looking at the electric drive concept had been the disadvantages of the hydraulic motor. For sure, hydraulics as well as electro-mechanics have their strengths and weaknesses.

But not only the higher CAPEX of the hydraulic version, not at least the hydraulic room, is disadvantaging. The start-up of such a complex system means a huge effort at the construction site. Furthermore, the OPEX are more and more in the focus of most operators. A further disadvantage is the viscosity of the hydraulic oil depending on the outside temperatures – especially in colder regions e.g. Russia. Based on all this, the hydraulic drives need distinctly more maintenance compared to their electric relatives. These arguments convinced Holtec to develop an alternative drive concept based on an electric drive.

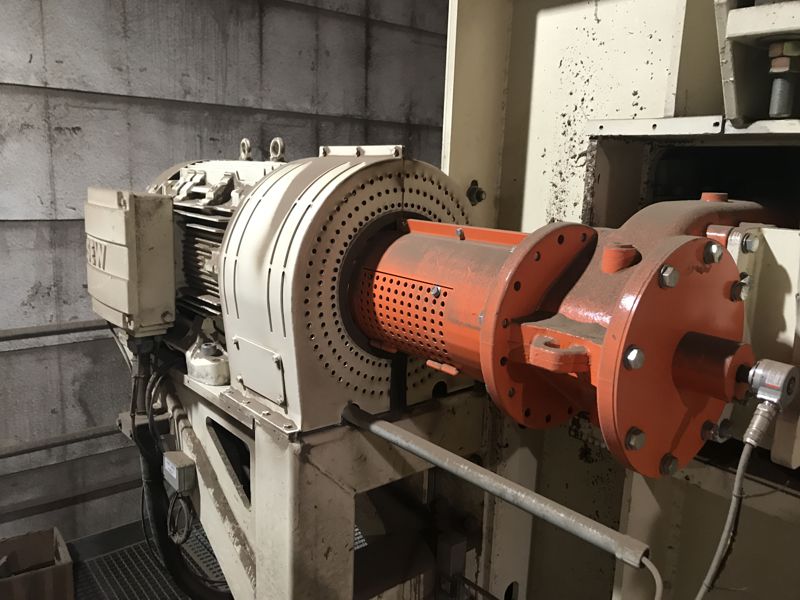

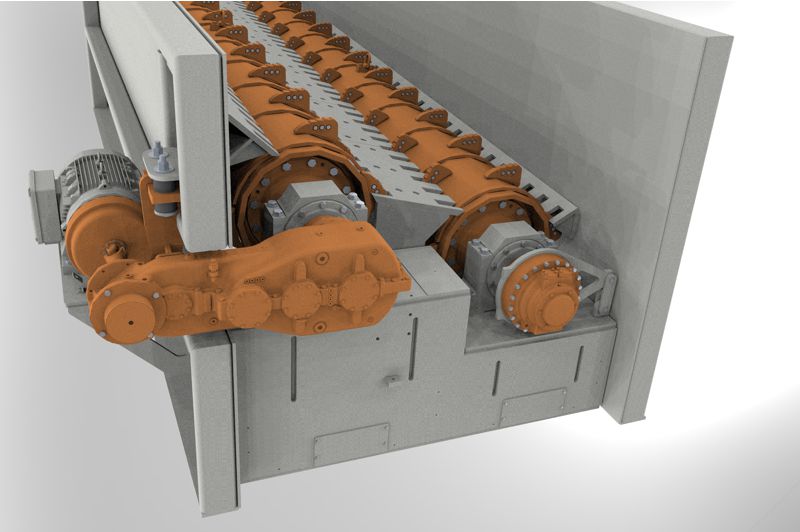

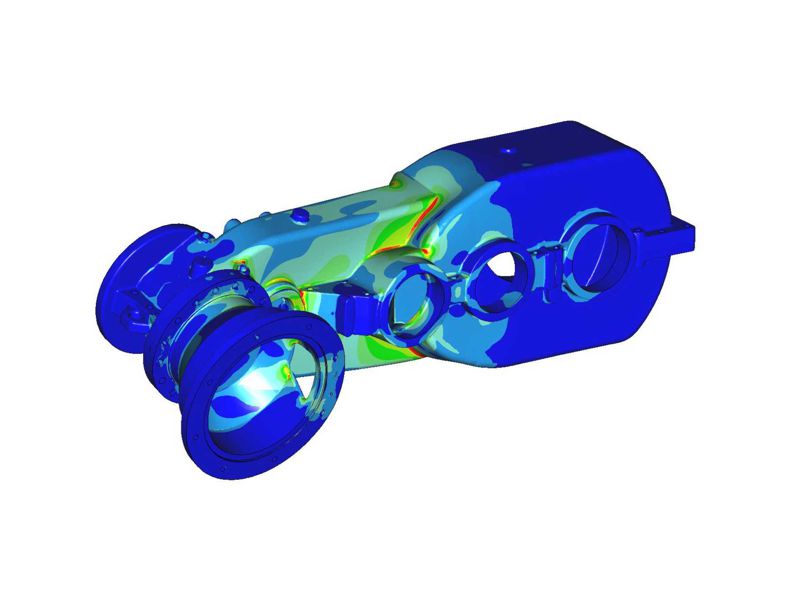

It soon became clear that a standard gearbox would not work because of the limited installation space and the unavailability in case of need for maintenance. But in no way this was any hindrance to the Holtec engineers. They developed their own gearbox. Together with a specialised engineering consultant, a very stable helical gearbox with a huge torque of > 35,000 Nm was designed. In order to balance the weaknesses of the electric drive in terms of pressure peaks, there is a fluid coupling installed with the gearbox as torque limitation.

Further considerations that influenced the design, were the special demands of the wood-based material industry in terms of maintenance and short shut-down times in case of services. In order to remove the gearbox in short time, there is a separating flange between rotor shaft and gearbox. The electric drive is arranged outside the machine so that it is easily accessible. In order to reduce torsional moments from the gear housing, motor and gearbox are connected with a cardan shaft. All in all a robust and long-lasting alternative to the hydraulic drive with focus on low operating costs.