Robust conveying technology for demanding applications in the wood-based materials industry

The production of LVL (Laminated Veneer Lumber) and PLY (Plywood) places the highest demands on log handling. To achieve first-class results in veneer and paneld production, logs must be cut with absolute precision and optimally conditioned.

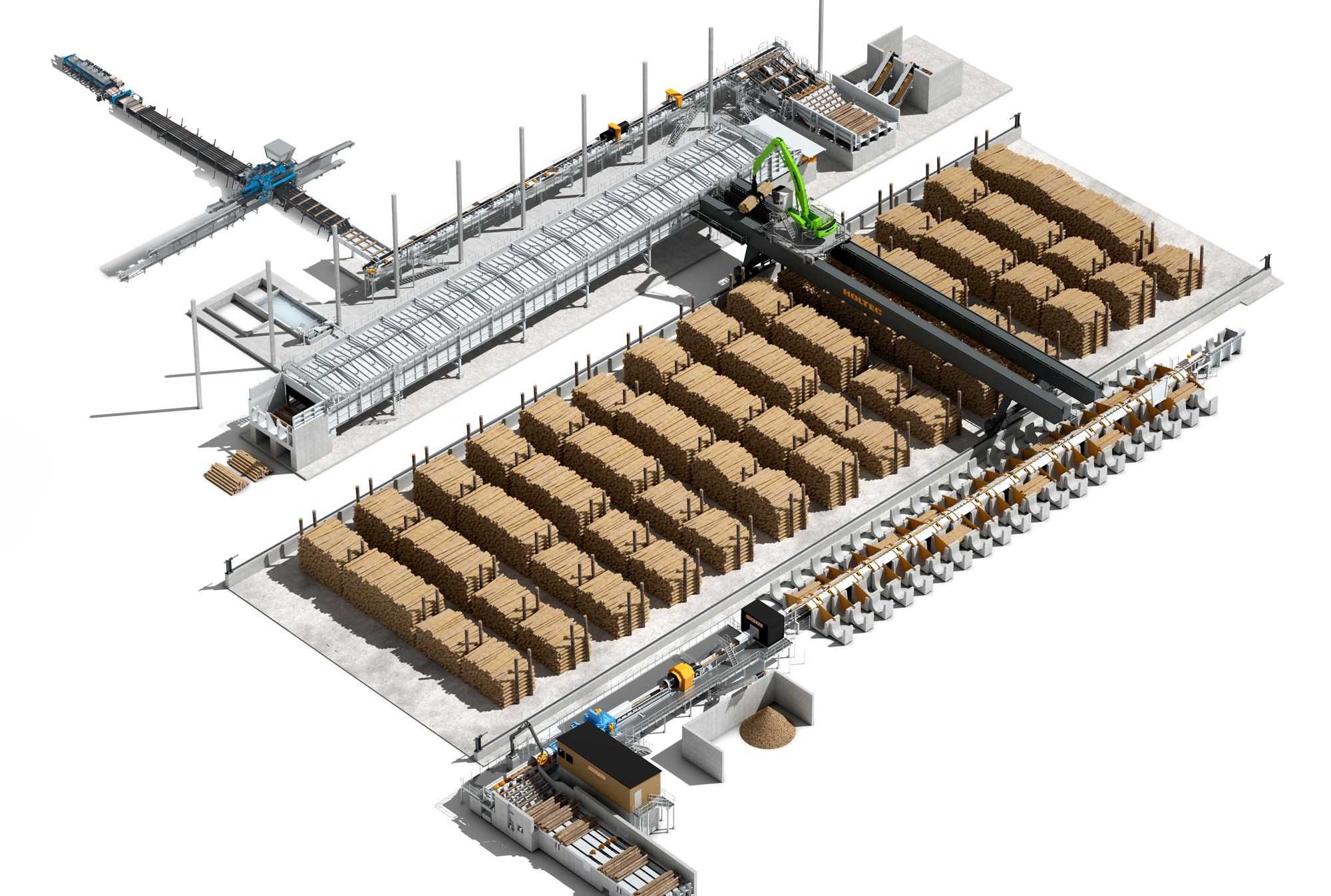

This is were HOLTEC demonstrates its particular strength: we combine the know-how from two worlds. From the sawmill industry we bring our expertise in precise conveying, separating and cutting of logs. From the wood-based materials sector, we draw on our experience with tough 24/7 operating conditions and the need for extremely robust, durable technology. We combine these two disciplines into customised complete solutions, tailored to the specific requirements of LVL and PLY production.

Our systems cover the entire scope of log handling: from the loading, sorting and cutting to conditioning and integration into subsequent processes. With more than 350 completed projects and our deep engineering expertise we deliver turnkey concepts that unite efficiency, precision and maximum availability.

With HOLTEC you benefit from everything from a single source:

- Accurately cut logs for precise veneer dimensions

- Optimal conditioning for superior wood quality

- Seamless material flow without bottlenecks

- Reliable technology for the continuous industrial operation