PELLETS

Logs as raw material source –

flexibility in pellet production

In the past years, pellet plants have primarily relied on wood chips from sawmills as the raw material for producing high-quality wood pellets. This forms the ideal basis for premium pellets, commonly used in private households for stoves and boilers.

However, the global supply of wood chips is steadily declining, which is why logs are becoming increasingly important as an alternative raw material source for pellet production. In addition, producing wood chips in-house provides greater flexibility and independence in raw material sourcing.

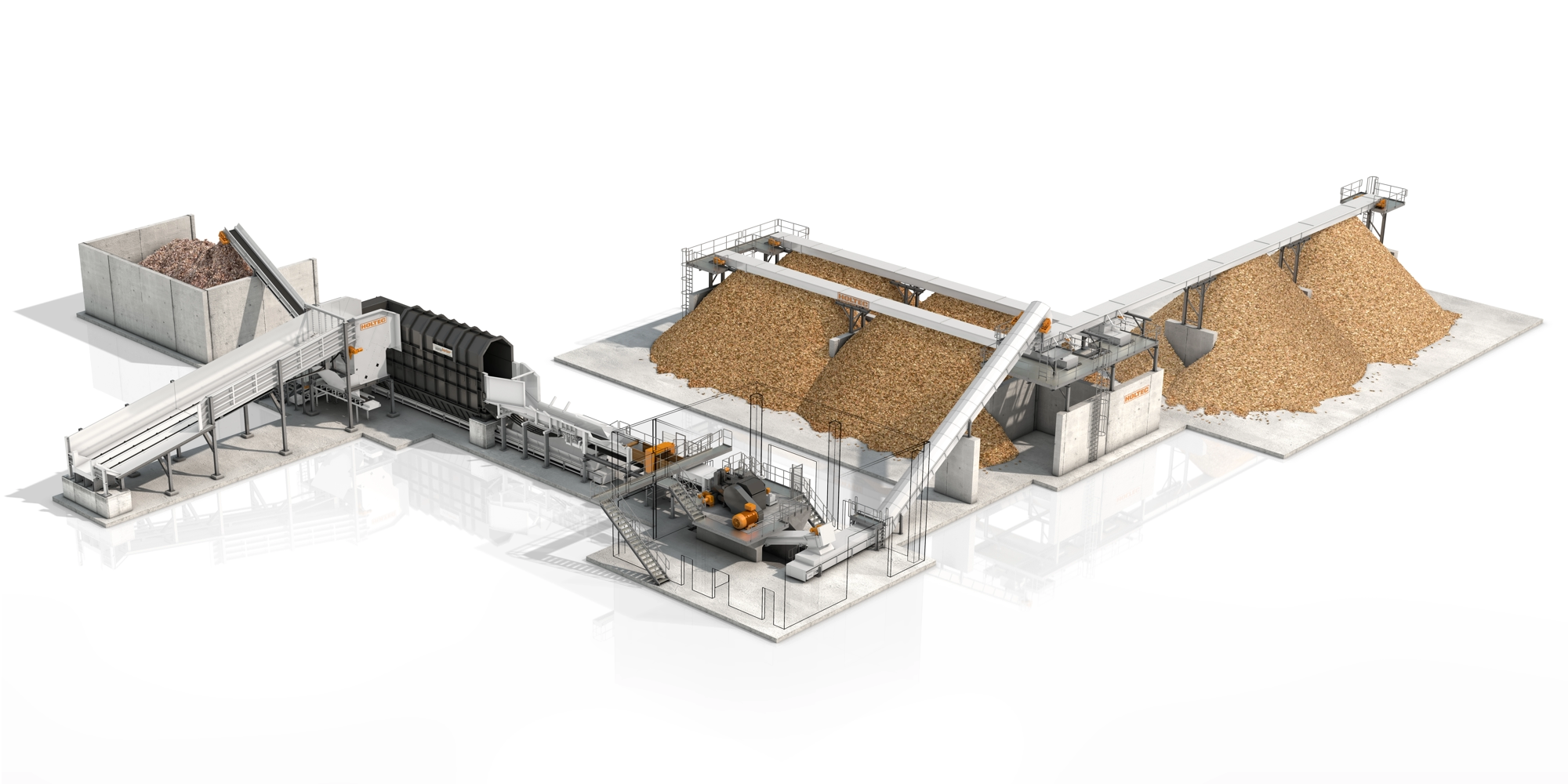

Holtec is responding to this development with customised wood yard concepts that enable the efficient processing of logs, depending on wood quality and the required production capacity. Our solutions ensure the production of high-grade wood chips – a key prerequisite for manufacturing first-class pellets.

As the supply of wood chips, a by-product from sawmills, continues to decline, more and more pellet plants are turning to logs as a raw material to secure production.

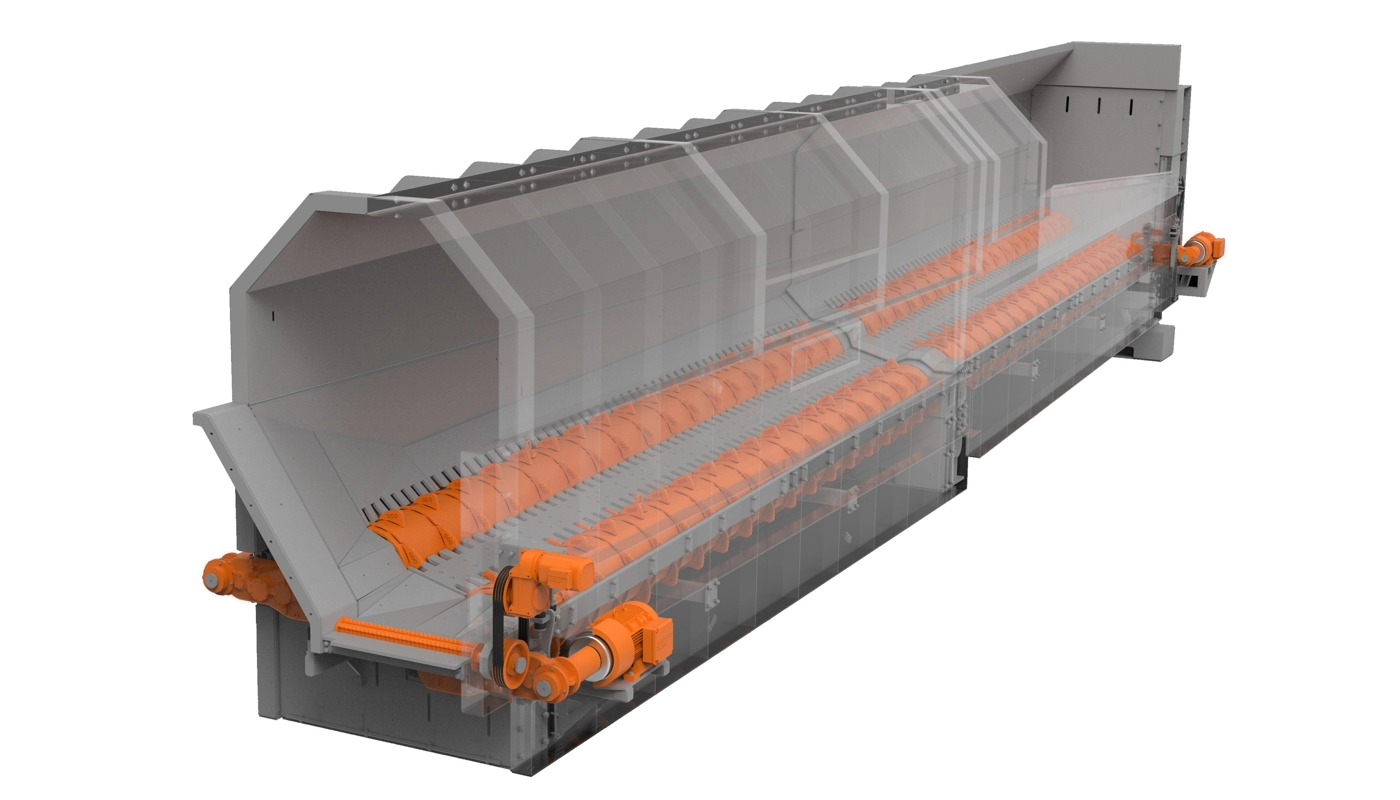

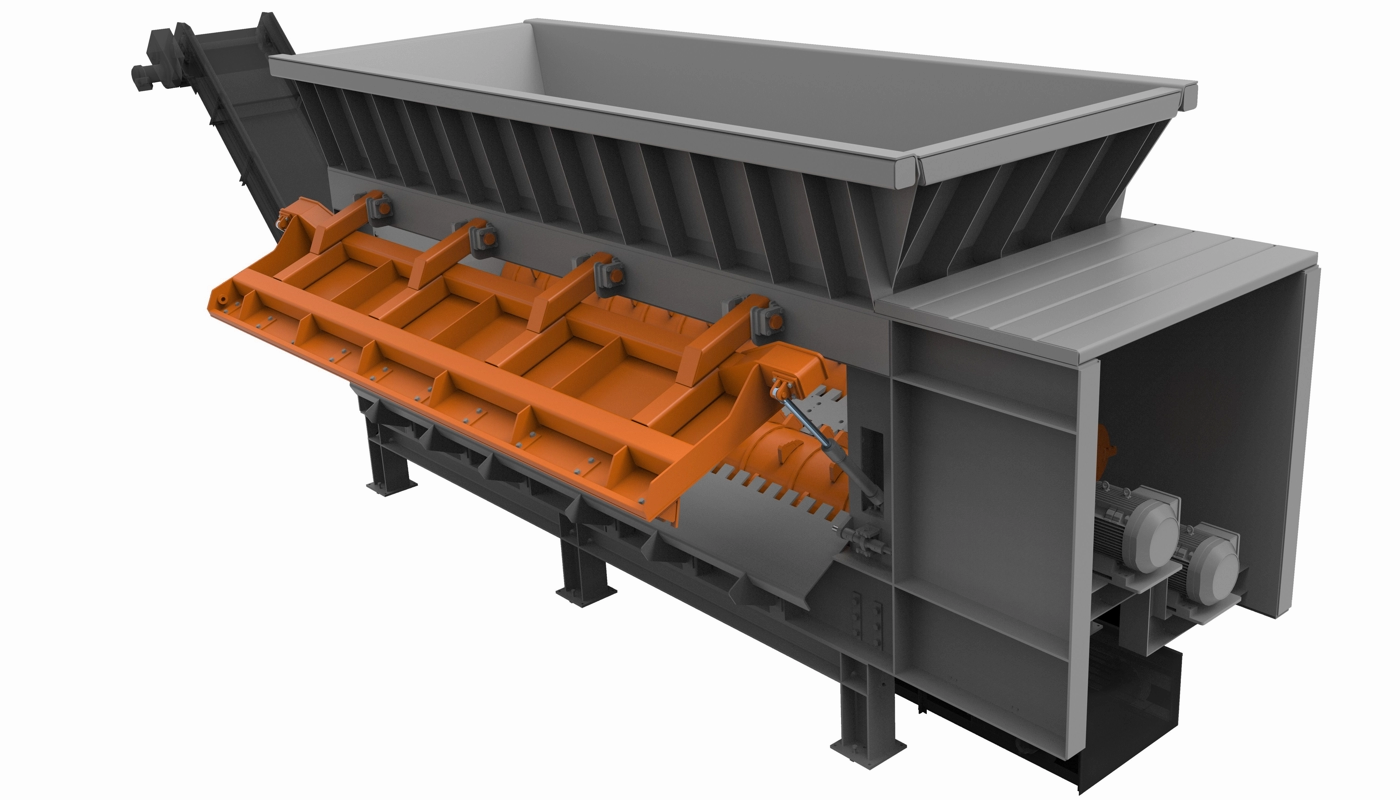

For the production of high-quality, standard-compliant pellets, log debarking is essential. Industrial logs with curvatures, as well as short logs with small diameters, can be debarked most efficiently using a Rotary Debarker.

In this machine concept, the bark is broken open by cam-equipped shafts during longitudinal transport and separated from the log through rotation.

The Vario-Barker, developed by Holtec, has already been successfully implemented more than 15 times and is the only machine on the market with a hydraulically adjustable inclination. This allows the debarking performance to be precisely adapted to the specific wood characteristics.

The use of industrial wood extends the procurement criteria for logs – resulting in lower costs and greater flexibility in raw material supply. Thanks to the modular design of the Rotary Debarker, performance is virtually unlimited in terms of scalability. For smaller capacities and stand-alone-operation, our Batch-Debarkeris ideal and can, if required, be gradually integrated into a stationary plant concept.

No matter what your requirements are – HOLTEC offers suitable plant concepts for all performance classes.

Wood yard with Rotary Debarker and drum chipper for the production of wood chips for pellet production. Capacity approx. 30–40 t bd/h.

Here you can dowload our current brochures: