OSB

Reliability that sets standards –

High-performance OSB plants for

maximum availability

The production of OSB boards is a highly complex process in which every machine and system is seamlessly interconnected - from log handling to board stacking. A failure of a single component can, in the worst case, bring the entire production line to a standstill. This is precisely where maximum reliability is essential - with technology from specialists who know exactly what counts.

With more than 20 implemented debarking and flaking lines Holtec has impressively demonstrated expertise in log handling: robust conveying systems, well-thought-out engineering from the steel structure to the safety concept - and a passion for detail. That makes the difference!

But it is not only about simply linking individual machine parts. When all components are perfectly matched and work together in harmony maximum plant availability can be guaranteed.

We develop tailor-made wood yard solutions – exactly to your requirements. We integrate flakers from all leading producers into a coherent overall concept - and in cold-climate regions, naturally including conditioning systems with the necessary heating technology. For flaker infeed we offer flexible solutions ranging from crane and excavator handling to the proven pocket loader system.

Challenge us!

Nine out of ten European OSB mills already place their trust in Holtec technology - for both new plants and modernisations.

We are proud to say: Holtec – No. 1 in OSB!

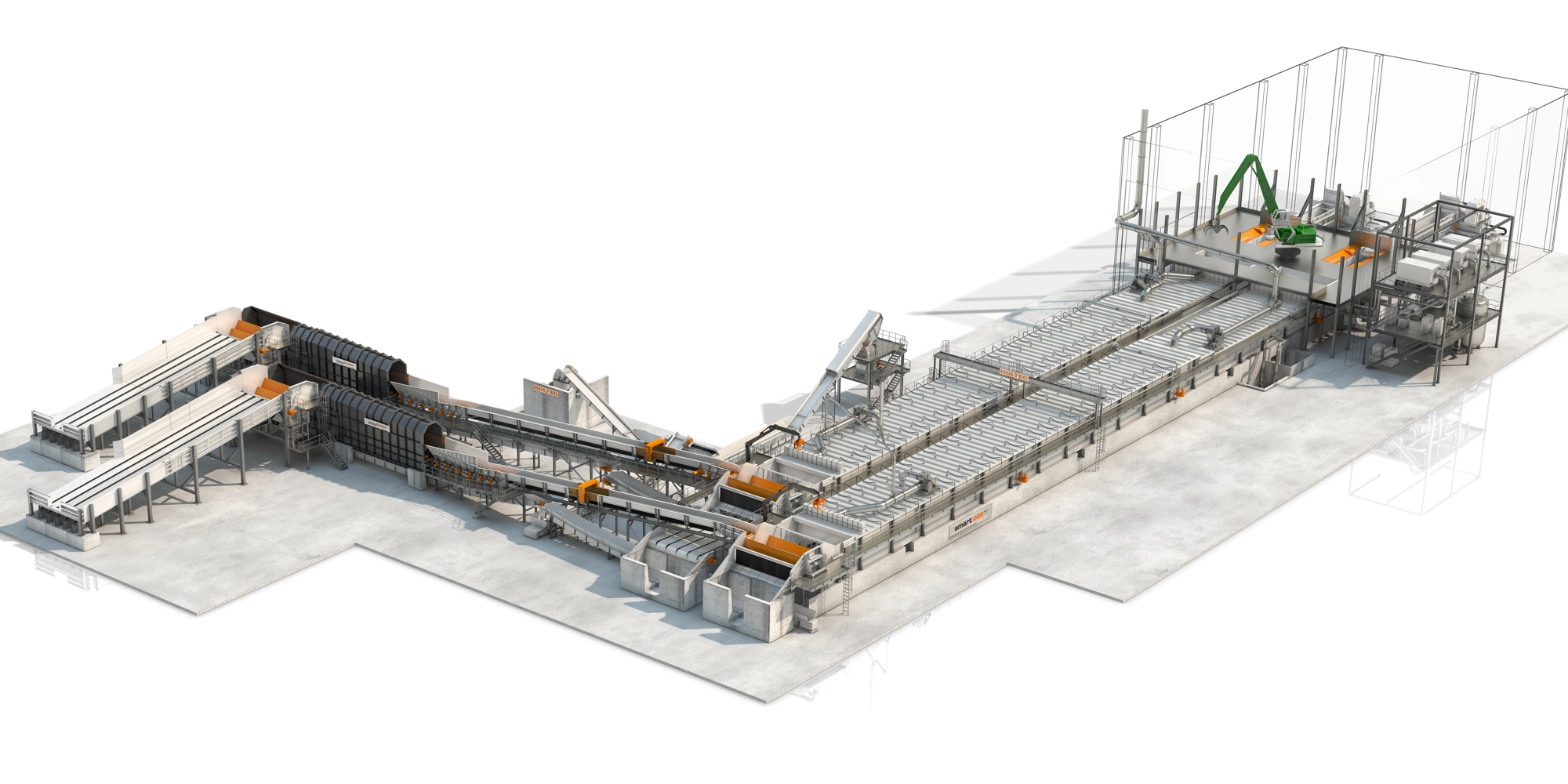

Debarking by Rotary Debarker and log de-icing with hot water spraying. Strander feeding with stationary hydraulic crane. Capacity approx. 80 t bd/h. Expandable to 3 stranders for capacities > 100 t bd/h.

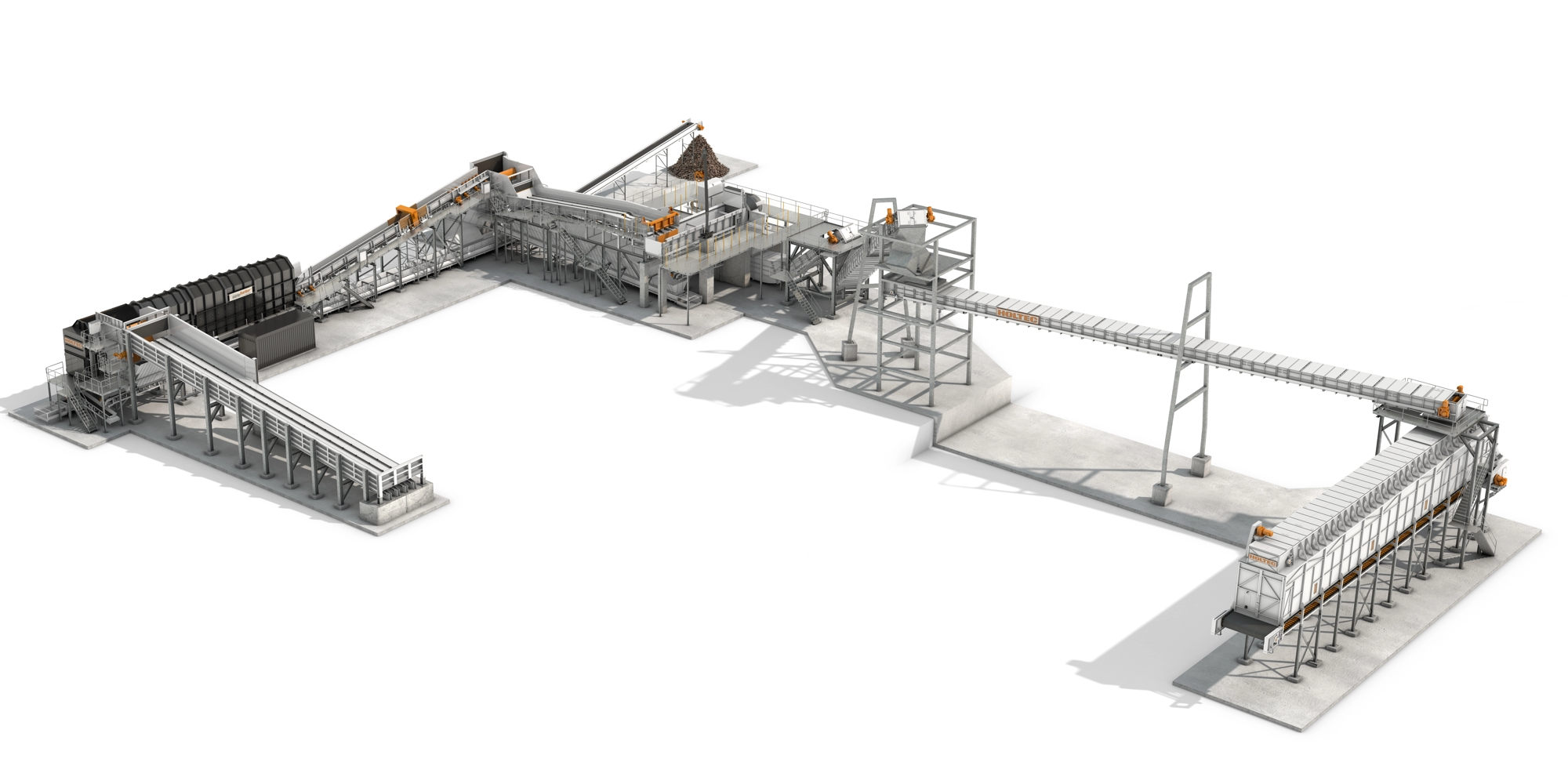

Plant layout for a OSB wood yards with only one feeding. OSB wood yard with Rotary Debarker and strander including feeding pusher. Chip handling with trough chain conveyors and wet chip bunker. Capacity approx. 40–50 t bd/h.

Here you can download our current brochures: