MDF

Solutions for efficient

wood-chip production

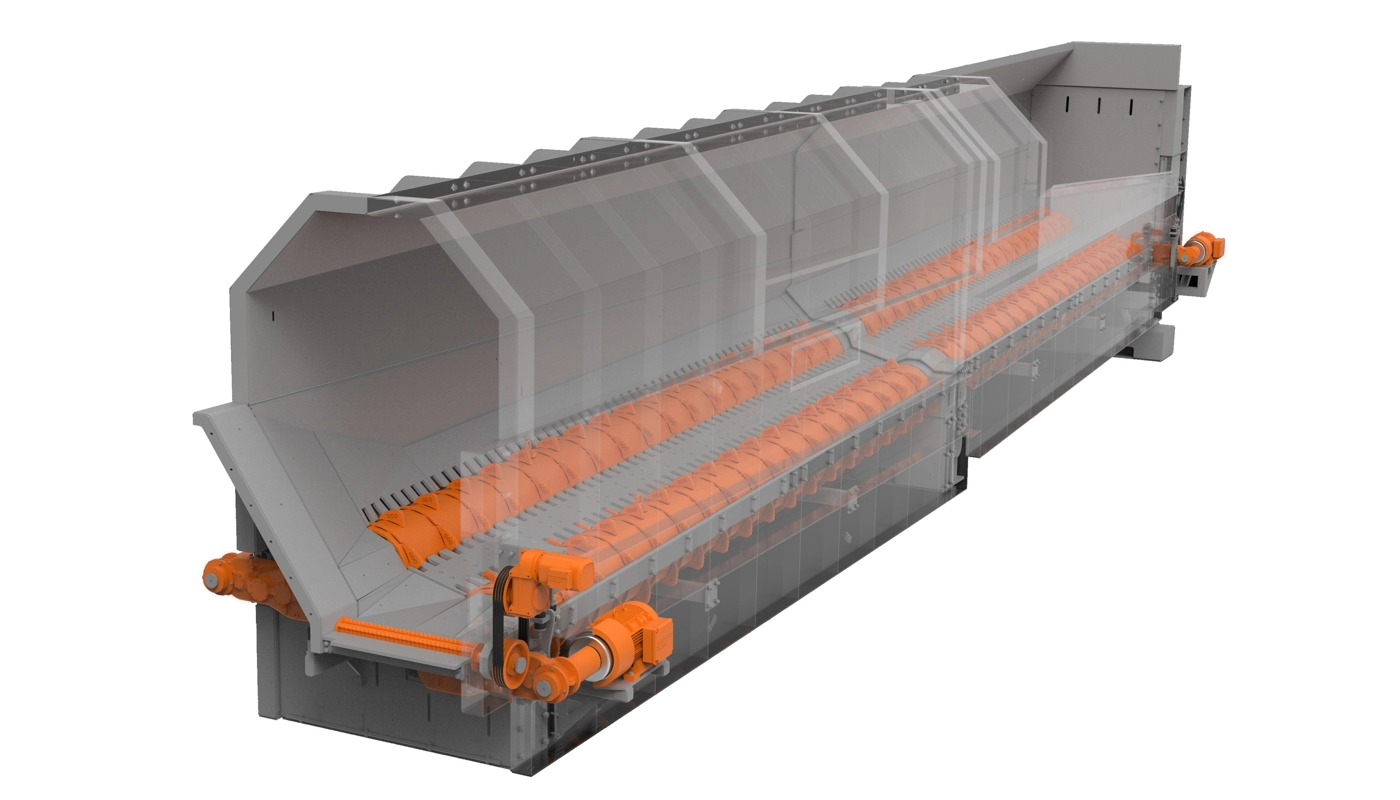

High-quality products such as MDF and HDF boards require first-class wood chips as base material. Debarker and disc chipper play a crucial role in this process. To ensure both machines operate at their full potential, intelligent and reliable conveyor technology is indispensable.

Holtec offers customised solutions that guarantee the optimal integration of equipment. Our systems are designed for different capacity ranges, namely wood chips from 30 to 150 t bd/h, delivering maximum efficiency in production.

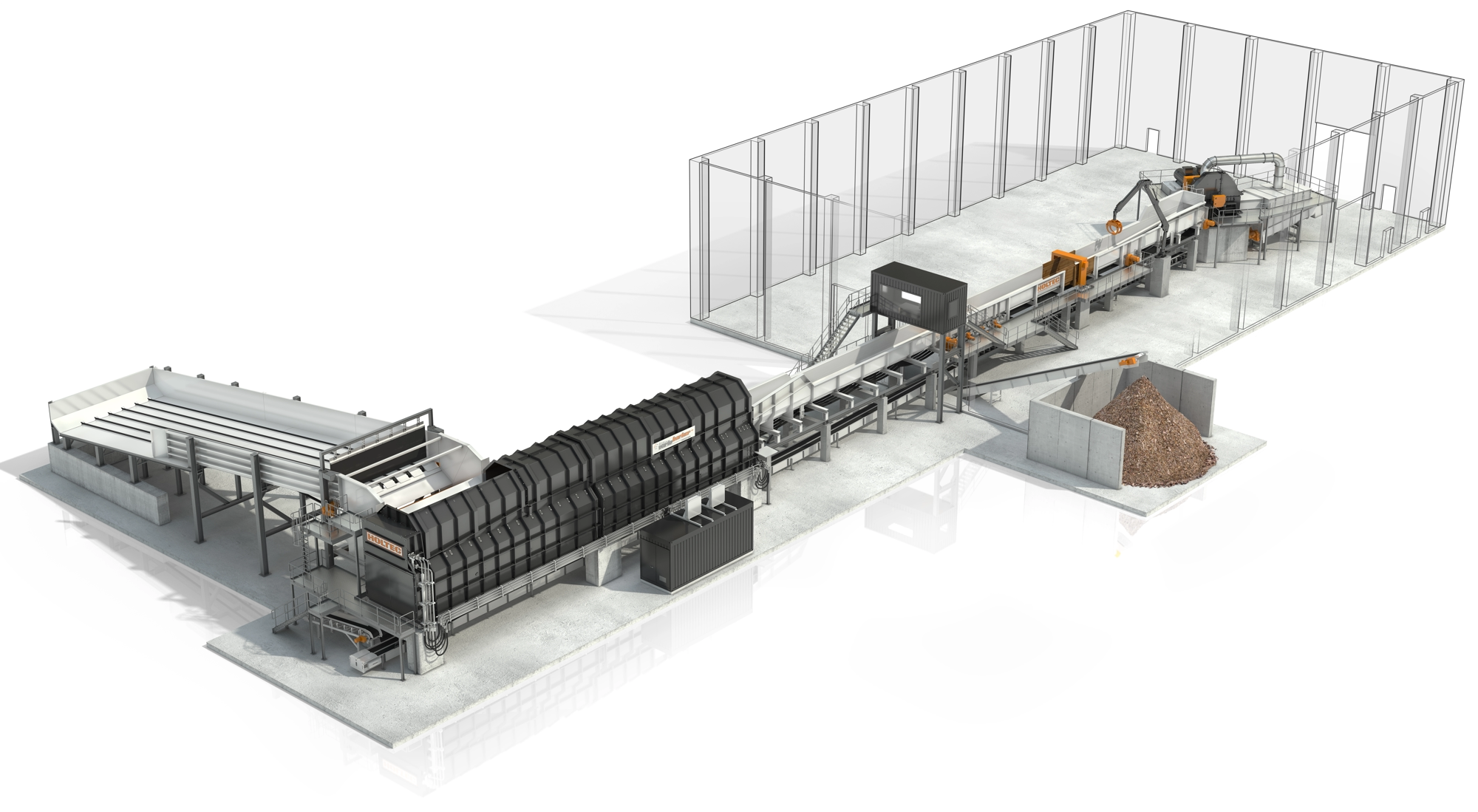

Wood yard with Rotary Debarker and disc chipper to produce wood chips for MDF production. Capacity approx. 100 t bd/h.

Here you can dowload our current brochures: