Maximum efficiency in

handling short logs

Holtec sets the standards

Holtec bar sorting lines have been continuously developed and refined over the past decades. Through close collaboration with our customers, we have been able to create new solutions and optimise existing systems continuously.

With innovative technologies such as the Chainless system for efficient log separation as well as the LogRunner for log acceleration and gap optimisation, we are setting new standards for both small and large-scale systems.

Thanks to over 50 years of experience, ranging from small family-run businesses to international corporations, we offer a broad product portfolio for sawmills of all sizes. Our individual designs, precisely tailored to the respective application, make Holtec a reliable partner for customised solutions for bar sorting lines.

Holtec sets the standard in system technology diversity. For every task we work closely with our customers to develop the optimal concept. Our systems are planned and designed by a highly qualified team of technicians and engineers. Installation and start-up are carried out by our specialists and a comprehensive full-service package is always available for all mechanical and electrical aspects.

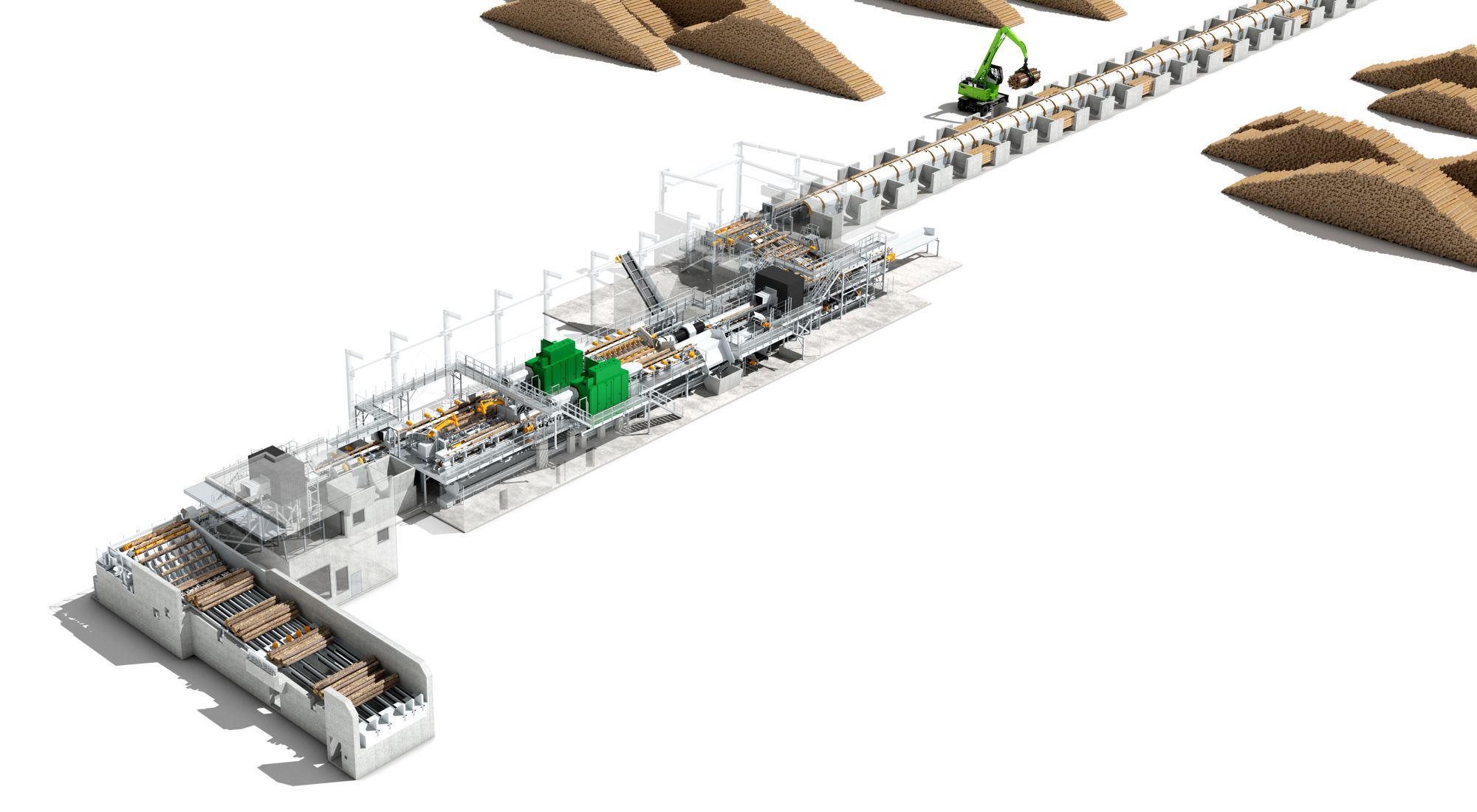

View of a typical plant layout for a feeding system for short logs: