Gamechanger in

Log handling

Innovative and sustainable concepts

for the future-oriented log handling

New approaches in log handling

The demands on the wood industry are changing. Rising operating costs, pressure for sustainability and the need for greater efficiency call for new strategies. Especially in log handling there is a significant potential to make processes more economical and climate-friendly. Traditionally used diesel-powered industrial trucks generate high maintenance and operating costs - often up to 100,000 € per machine annually - and require complex infrastructure. This is exactly where HOLTEC introduces a completely new approach: the VPK Loghandler.

VPK Loghandler – game changing technology

Together with experienced partners from the crane construction and handling technology, HOLTEC has developed a fully electric portal crane concept that revolutionises log handling. The VPK Loghandler offers:

Sustainability meets efficiency

The wood industry is undergoing a profound transformation: rising costs, stricter climate regulations and the need for sustainable process. With the VPK Loghandler HOLTEC offers a solution that combines ecological responsibility with economic efficiency - paving the way for the sawmill of the future.

| Shortage of skilled workers |

|---|

| Qualified excavator operators are becoming increasingly difficult to find. Understaffing is leading to a growing loss of productivity. In addition, cramped cabins, heat and dust are deterrents for potential new employees. |

| Work productivity |

|---|

The performance of the drivers has a significant impact on the productivity of the sawmill. Unskilled workers require long training periods, while the daily form of experienced drivers greatly influences efficiency.

|

| Sustainability |

|---|

| The pressure on companies to reduce CO₂ emissions is growing to emissions trading, ESG requirements and CSRD reporting. Diesel-powered machines are increasingly coming under scrutiny. |

| Space requirements |

|---|

| Traditional log yards with mobile machinery can occupy up to 40% of the operating area. Valuable space for expansion or new production facilities is lacking. |

| Process complexity |

|---|

| The variety of products and the demands on wood logistics are constantly increasing. Without intelligent wood yard management there is a risk of incorrect storage, inefficient processes and declining performance. |

| Occuptational safety |

|---|

The safety of employees is becoming increasingly important. Workplace accidents are on the rise in wood yards, leading to high costs, legal consequences and reputational risks.

|

| Wear & Maintenance |

|---|

| High wear and demanding maintenance of diesel-powered machines drive up operating costs. At the same time, there is a lack of qualified personnel for servicing and repairs. |

Conclusion:

The wood industry is under economic, ecological and organisational pressure:

It is precisely these challenges that create the need for innovative technologies such as VPK Loghandler, which simplify and optimise processes while also making them more sustainable.

| Sustainability |

|---|

| Up to 80% less CO₂ and significantly reduced emissions. No large-scale sealing required - lower costs and better environmental balance. |

| Efficieny |

|---|

Significantly lower operating costs thanks to low-maintenance electric drive and long service life.

|

| Space optimisation |

|---|

| Up to 50% more storage volume through intelligent use of space and flexible layout organisation. |

| Safety and ergonomics |

|---|

| Optimal visibility, clearly defined safety areas and modern, attractive workplaces. |

| Future-proof |

|---|

| Partial automation and remote are operation possible - for maximum process optimisation. |

| Flexibility |

|---|

| Modular expandable concepts – from log feeding vehicle to digital wood yard management. |

For the development of the VPK Loghandlers we rely on a close and strategic partnership with SENNEBOGEN, one of the leading specialists in wood handling technology. Together, we have developed an entirely new concept for log handling that comines the advantages of state-of-the-art portal crane technology with the expertise of two technology leaders.

SENNEBOGEN contributes decades of experienc in hydraulic and drive technology as well as in the precise handling of large volumes of wood, while HOLTEC brings its expertise in engineering complete log yards and digital log yard management. The result of this collaboration is the VPK Loghandler - a fully electric, highly efficient and sustainable solution for log handling that sets new standards in performance, flexibility and energy efficiency.

This partnership represents more than the sum of two competencies: it demonstrates how joint development and mutual trust can enable innovations that meet the demands of modern sawmills and wood-based materials plants.

Together with SENNEBOGEN we are setting new standards in log handling.“

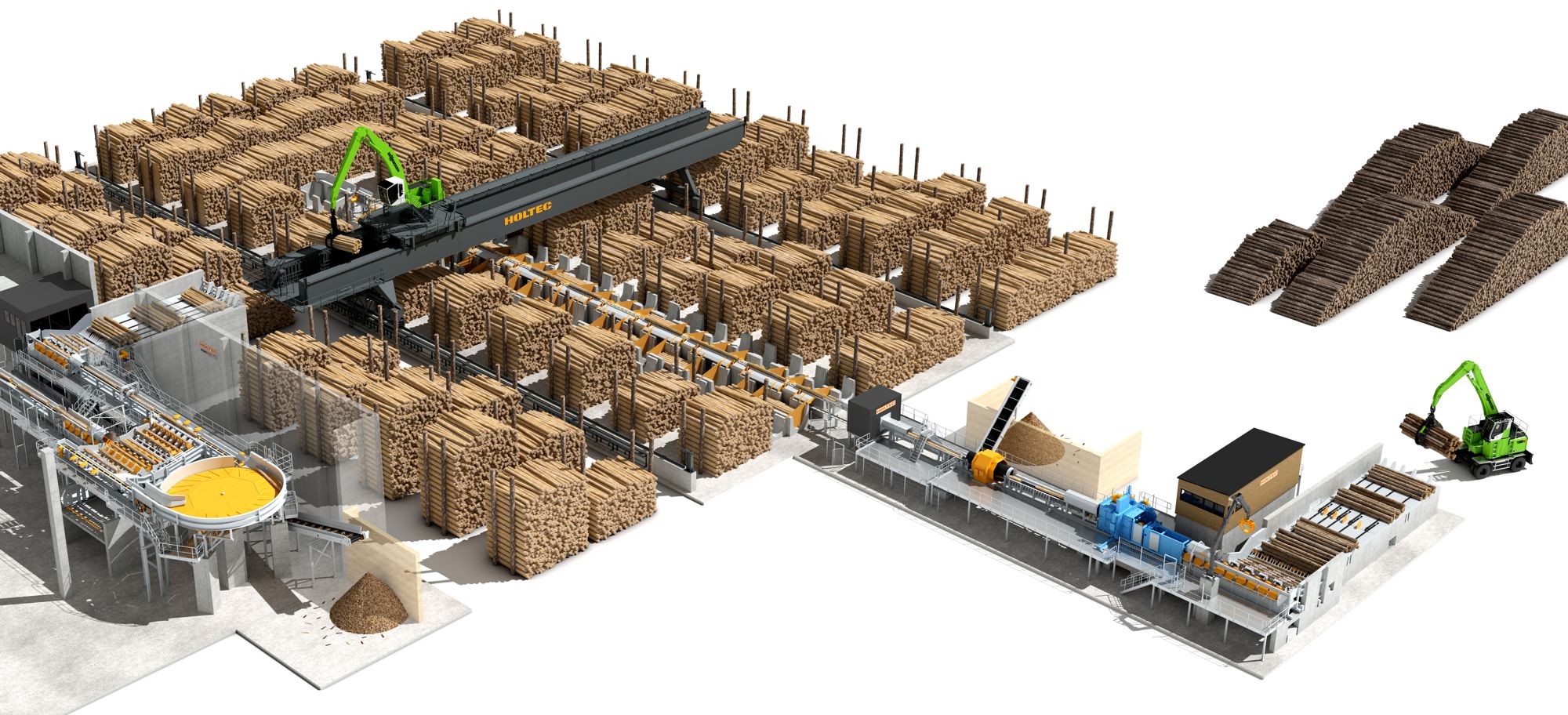

Possible plant layout for the sawmill industry. The VPK Loghandler as the central element in log handling for emptying the boxes and simultaneously feeding the saw line. Highly efficient operation with just one operator, even in limited space.

Possible layout for the wood-based material industry for a modern wood yard for feeding a rotary debarker, eg. in MDF, OSB or pellet production.