The sawmill of the future is far more than a modern production facility – it is an intelligent, interconnected hub within a fully digital and sustainable value chain. From log logistics to final product delivery, every process is captured, analysed, and controlled in real time. Sensors, AI, and automation enable a learning production system that adapts dynamically to material properties, order volumes, and energy requirements.

Digitalisation also lays the foundation for resource-efficient operations: optimised workflows, predictive maintenance, and data-driven decision-making help conserve energy, reduce waste, and maximise the value of increasingly scarce raw wood. This not only boosts efficiency but also contributes actively to a climate-friendly and resource-conscious wood industry.

Another key factor is the human element. Modern, ergonomic, and safe workplaces enhance the appeal of the sector and are essential for attracting and retaining qualified professionals. Only those who combine technology, sustainability, and good working conditions will thrive in the wood industry over the long term.

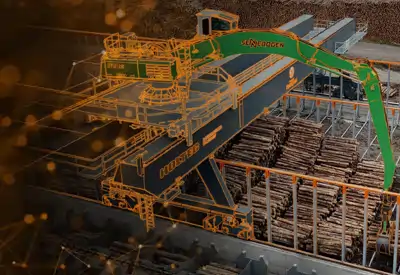

At HOLTEC, we are fully committed to driving this transformation – with a clear focus on elevating log handling to the next level. As specialists in the front end of the sawmill, we are advancing automation and digitalisation precisely where it all begins: in the efficient, sustainable, and human-centred handling of logs.