Precision in real time

AI brings intelligence to log handling

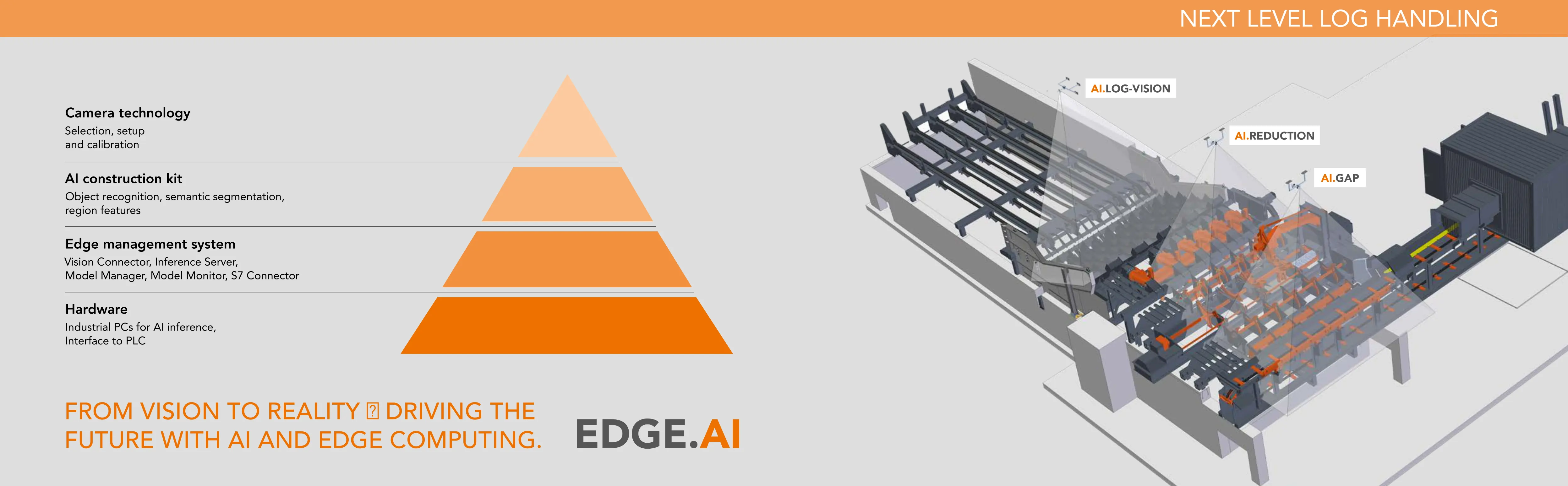

With EDGE.AI, HOLTEC elevates log handling to an entirely new level. Where manual interventions and rigid processes once prevailed, artificial intelligence and local real-time data now deliver enhanced efficiency, precision and reliability.

Visual log detection and gap optimisation are now fully automated – fast, robust, and error-free:

Enabled by edge computing technology, data processing takes place directly at the machine – locally, securely, and in real time. Your data remains on site, ensuring data sovereignty and uninterrupted operation even in unstable network environments.

EDGE.AI is more than just a technology – it is an essential component for the sawmill of the future. Production processes become smarter, more flexible, and more resource-efficient:

In collaboration with an experienced technology partner, HOLTEC has developed a modular, industry-ready system that can be flexibly scaled – from individual machines to complex production lines. EDGE.AI makes facilities robust, future-proof and transparent, paving the way for smart, digitally networked, and sustainable log yard operations.

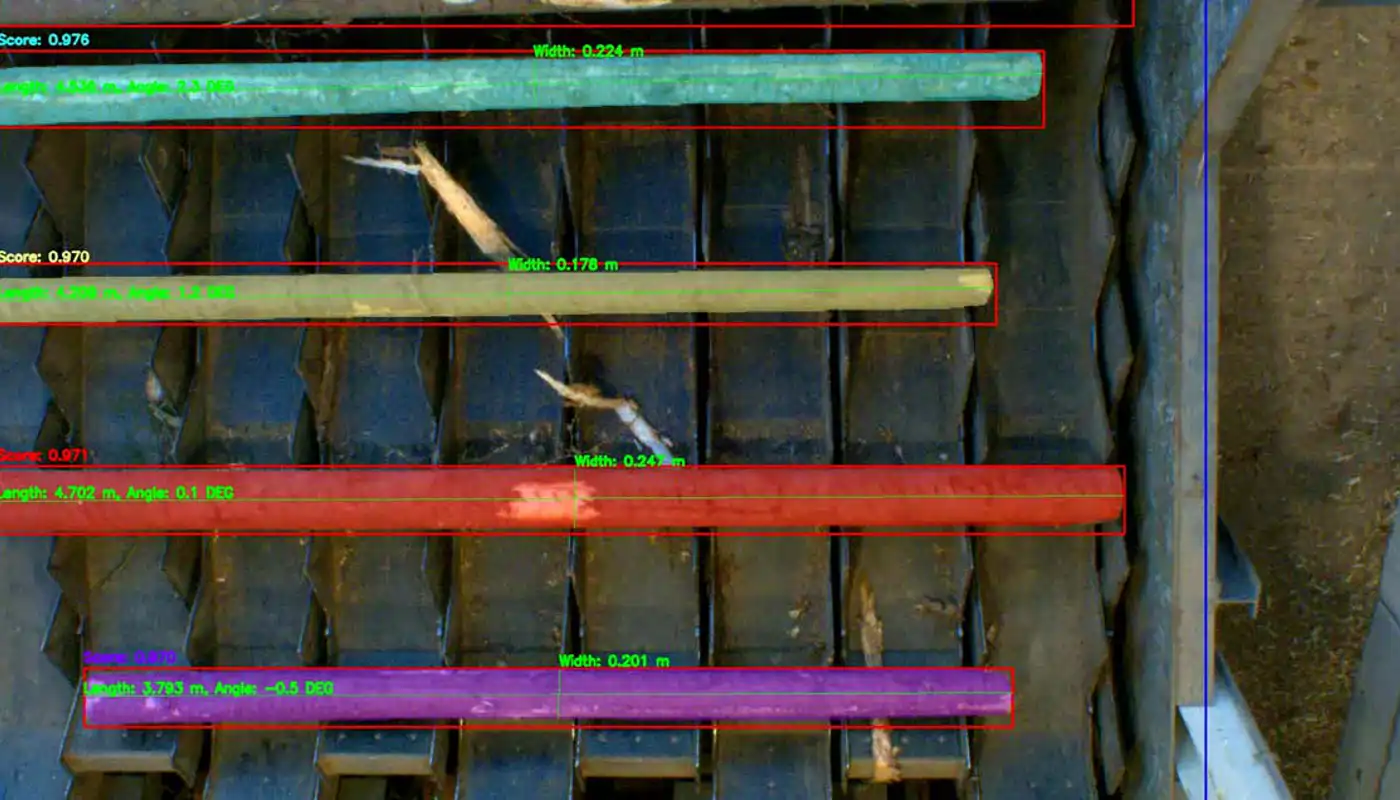

Even the most advanced saw line can only reach its full potential if logs are fed continuously and with precisely defined gaps. Efficiency and performance depend not only on the technology at the saw itself, but crucially on the intelligence of the upstream feeding system. This is exactly where AI.GAP comes into play: the solution was developed to bring greater precision to log handling at this critical interface. By ensuring consistently accurate gap formation, both throughput and yield can be significantly increased – and this applies to all cross transfers in log handling that may act as potential bottlenecks, decisively influencing material flow.

In many facilities, visual assessment of logs for butt reduction remains the standard practice. With AI.REDUCTION, this evaluation can be automated easily and reliably during cross transfer operations. Especially for monotonous tasks over extended periods, the AI takes over continuous monitoring – allowing human operators to focus on more demanding responsibilities such as quality assessment or maintenance. The algorithm continuously analyses diameter data and makes precise decisions independently

AI.LOG-VISION is designed to support a wide range of applications, including the monitoring, optimisation, and validation of process workflows across various use cases. Anomalies can be detected in real time, with automatic alerts or line stoppages triggered as needed. This significantly reduces downtime and the need for manual intervention to resolve disruptions. Additional use cases include monitoring log deck fill levels or detecting broken logs.