Holtec supplies log yard for VMG greenfield project

In its most recent project with the VMG Group in Akmene, Holtec once again demonstrated its strength as a log handling specialist – providing the ideal solution for LVL log preparation.

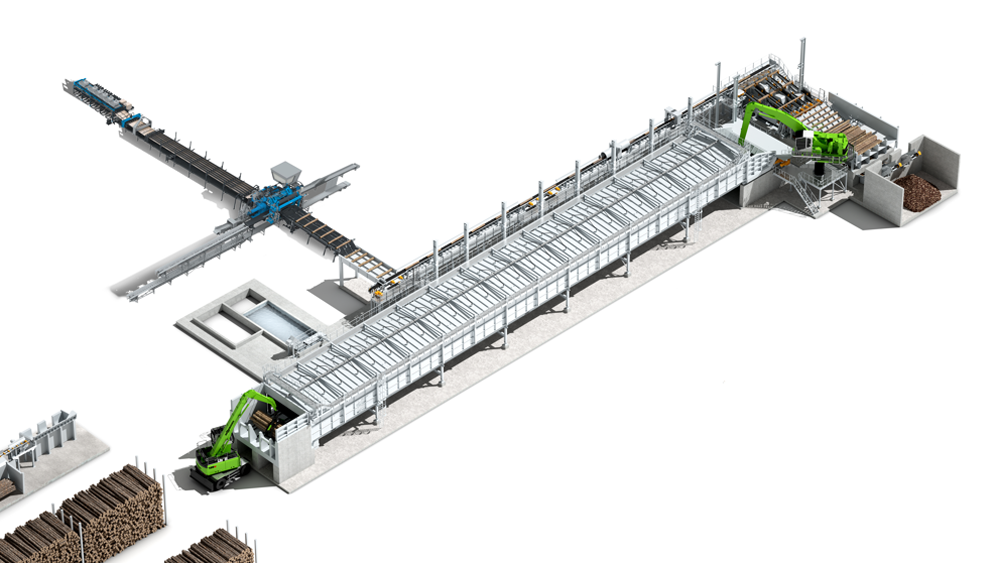

Our partnership with the VMG Group spans many years and is defined by mutual trust and close collaboration. We are proud to have now successfully completed our fourth and largest joint project to date. For this remarkable greenfield development in Akmene, in northern Lithuania, Holtec delivered a comprehensive solution for log processing. With this new facility, the VMG Group is entering the LVL and timber construction market. Once fully operational, the plant will produce up to 120,000 m³ of laminated veneer lumber per year for structural applications.

This project once again highlights Holtec’s capability to deliver innovative solutions for complex requirements – always in close and trusted cooperation with our partners.

Comprehensive solution for complete log handling

When entering the LVL sector, the VMG Group pursued the principle of sourcing as many key machines as possible from a single supplier. In 2021, Holtec was commissioned to develop a comprehensive solution for the entire log handling process at the new site. This included log sorting, log conditioning, log cross-cutting, and the feeding of the Raute peeling lines.

A central focus was placed on the conditioning of the logs, which functions as the pivotal element of the entire plant. On this basis, the project was structured to achieve a coherent and reliable overall concept.

The concept itself is based on proven approaches, as Holtec has already successfully implemented numerous conditioning plants. This wealth of experience played a decisive role in meeting the project’s high demands and in delivering a powerful and efficient solution for complete log handling.

Efficient and resource-saving conditioning

Holtec’s scope of supply begins with the log sorting system. The plant is designed for an annual throughput of 270,000 solid cubic metres and processes logs with diameters ranging from 180 to 600 mm and lengths between 4.0 and 6.5 metres.

The heart of the delivery is the continuously operating conditioning and preparation line. Depending on weather conditions and the season, Baltic pine logs are sprayed for around one day with hot water at approximately 70 °C, in order to achieve a core temperature of 30–40 °C. This ensures the logs are ideally prepared for the subsequent peeling process. Unlike conventional systems, in which logs are heated in basins, Holtec relies on a continuous spraying process. In this system, the logs are constantly sprayed from above, allowing for a significantly more efficient mode of operation. In addition, the process parameters can be individually controlled, while keeping fresh water consumption extremely low.

Thanks to the continuous mode of operation, the entire process could be largely automated, which was a decisive factor for the project. This combination of efficiency, controllability and automation highlights Holtec’s innovative strength and was a key reason for the company’s selection as partner.

+ 700

m³ logs

+ 70

°C hot water

+ 80

metre long tunnel

Logs sprayed with water in an 80 m long conditioning tunnel

Around 700 m³ of wood are processed in the 80-metre-long conditioning tunnel, with the system operating on a closed-loop circuit containing only 150 m³ of water. The water is purified through a multi-stage filtration process to safely remove dissolved wood constituents, coarse impurities and other contaminants from the system.

The process is designed to be particularly water-efficient: depending on the moisture content of the logs and ambient conditions, only 1–2 m³ of water per hour needs to be added to compensate for losses caused by evaporation and moisture absorption. The plant is primarily designed for pine and spruce, but allows for flexible adjustment of parameters to suit different wood species. The slightly inclined design of the conditioning tunnel enables the water to be drained rapidly by gravity alone in the event of an emergency stop. In addition, pivot-mounted foundations ensure that the thermal expansion of the 80-metre-long steel vessel is safely accommodated – particularly under the harsh Baltic winter conditions.

Seamless integration with the LVL plant

After around one day in the system, the logs are continuously removed by a Sennebogen log handler and transferred onto a step conveyor leading towards the production hall entrance. Four circular saw blades ensure a clean trimming cut and the optimal log length for the subsequent peeling process.

Before the logs are handed over to the LVL plant of Finnish industry specialist Raute, they pass through a final 2D measurement system for detecting oversize diameters, followed by a metal detector.

With this well-thought-out concept, Holtec has once again succeeded in fully convincing its Baltic customer — marking the fourth successful collaboration to date.