Verarbeitung von Rundholz

– am besten mit HOLTEC!

Der Anlagenbau für die Holzindustrie richtet sich bei HOLTEC nach den Vorgaben und Anforderungen der Kunden und nicht nach den Beschränkungen der Technik. Wir entwickeln innovative Produkte, anwenderorientierte Lösungen und bieten individuellen Service

– seit 50 Jahren.

Vielseitige Paketkappsägen runden unser Portfolio ab.

News und Referenzprojekte

Erich Poth blickt auf stolze 45 Jahre bei Holtec zurück

Der 01. August 1978 war ein Dienstag. Boney M. war mit dem Hit „Rivers of Babylon“ an der Spitze der deutschen Single Charts und die griechische…

Erfolgreiche LIGNA 2023

1300 Aussteller, 80.000 Besucher auf 114.000 m2 Ausstellungsfläche... die diesjährige LIGNA endete im Mai nach fünf Messetagen mit einem…

Neues Portalkran Konzept bei DOLD in Buchenbach

Die Anforderung an nachhaltige Prozesse sind unter anderem, die ökologische Effizienz des Unternehmens langfristig zu verbessern, ohne die…

Nach 34 Jahren in den Ruhestand verabschiedet

„Eine Legende verlässt das Gelände“ - unter diesem Motto verabschiedeten die Vertriebsmitarbeiter Erwin Franzen nach 34 Jahren Ende August aus dem…

Holtec ist Preisträger bei den German Innovation Award 2022

Mit der Serviceplattform „Holtec mobile Services“ revolutioniert die Holtec GmbH & Co. KG den Kundenservice.

Die neue App bündelt die digitalen…

Sechs neue Auszubildende zum 1. August begrüßt

Herzlich willkommen heißen wir unsere fünf neuen Azubis in Blumenthal und einen Neuen in unserer Niederlassung in Jänkendorf.

Während einer…

Holtec entwickelt eigene App

Holtec entwickelt eine eigene App und bündelt zukünftig alle Services unter dem Tool: HOLTEC mobile services.

Mit Herzblut und Leidenschaft haben wir…

Neuer Holzplatz bei Dünnplattenspezialist Homanit in Losheim

Im letzten Jahr lieferte Holtec für den Dünnplattenspezialisten Homanit GmbH & Co. KG in Losheim am See einen komplett neuen Holzplatz. Dies ist…

Gemeinsam gegen Corona

Einen exklusiven AOK/BGF Booster-Impftermin konnten wir heute auf dem Holtec Firmengelände wahrnehmen. Schon am frühen Morgen fuhren die AOK

und das…

Wir sind wieder auf Kurs

Dank vieler helfender Hände unserer Mitarbeiterinnen und Mitarbeiter und deren Familien und Freunden konnten wir in kurzer Zeit unsere…

Auch HOLTEC von Flutkatastrophe betroffen

Auch die Firma Holtec wurde von dem Starkregen schwer getroffen. Unsere Produktion wurde völlig überflutet. Wasser und Geröllmassen haben Wände…

Rundholzplatz bei Eigelshoven in Würselen nach Erweiterung erfolgreich in Betrieb genommen

Das Sägewerk, Gebr. Eigelshoven produziert hochwertiges Listenbauholz, Dimensionsware, Vorratskantholz, Dielen und Schalung. Auf einer Gesamtfläche…

Gelo Timber in Wunsiedel - Schwachholz-Sägewerk nimmt Fahrt auf

Eines der modernsten Schwachholzsägewerke Deutschlands, Gelo Timber in Wunsiedel, geht nach 11-monatiger Bauzeit in Betrieb.

Sägewerksneubau best Wood SCHNEIDER®/Eberhardszell setzt neue Maßstäbe

Das mittelständische Unternehmen best wood SCHNEIDER GmbH mit Produktionsstandort in Süddeutschland setzt mit dem geplanten Sägewerksneubau neue…

Gesundheit an erster Stelle! Flexibilität und digitaler Service gefragt.

Die Gesundheit der Mitarbeiterinnen und Mitarbeiter und unserer Kunden steht für HOLTEC an erster Stelle.

Um Sie zu schützen, vermeidet unser…

HOLTEC feiert 50-jähriges Jubiläum!

Einen besonderen Anlass zum Feiern gibt es 2020 für HOLTEC: Das 50-jährige Firmenjubiläum!

Im Jahr 1970 wurde das Familienunternehmen von mehreren…

Neue Rundholzsortierung für die HASSLACHER Gruppe am Standort Preding, Österreich.

HASSLACHER PREDING Holzindustrie GmbH vertraut erstmalig in der Firmengeschichte auf HOLTEC

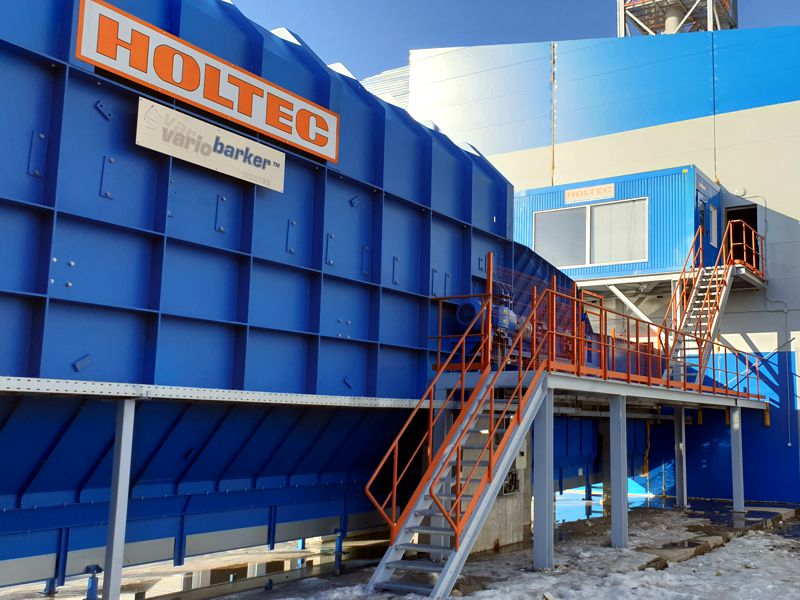

Produktionsstart bei Altailes Pavlovsk - Erster HOLTEC Rotary Debarker mit elektrischem Antrieb in Russland

Die Altailes Forest Holding Company wurde 2007 gegründet und umfasst 17 Unternehmen mit insgesamt 3.700 Mitarbeitern. Von der Russischen Förderation…

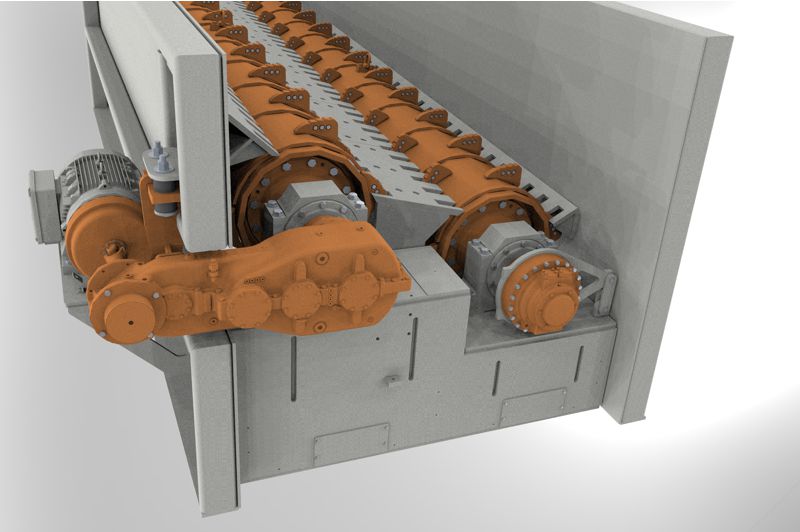

Rotary Debarker: Elektroantrieb als wirtschaftliche Alternative zum Hydraulikmotor

Geringerer Energiebedarf und reduzierte Wartung als Vorteile für Betreiber

HOLTEC bildet sechs neue Azubis aus

Wo beginnt man eine Ausbildung mit einer Azubi Rally oder einem Azubi Einstiegs-Seminar? ....

Nach 46 Jahren verabschiedet

Am 31.07.2019 war es soweit. Nach 46 Jahren bei der Firma HOLTEC ging auch der letzte Arbeitstag für Valentin Huppertz zu Ende.

Neuer Laubholz-Rundholzplatz für französischen Sägewerker Huberlant

Bereits im Mai letzten Jahres erhielt die Firma HOLTEC von der Firma Huberlant den Auftrag zur Lieferung eines Rundholzplatzes für Laubholz. Generell…

Erster Rücken Gesundheitstag bei HOLTEC ein voller Erfolg

Das BGF Institut Köln führte am 11. Juli in Zusammenarbeit mit der AOK Rheinland/Hamburg den ersten Gesundheitstag „Rücken“ in den Aufenthaltsräumen…

Erfolgreicher Messeauftritt auf der LIGNA in Hannover

Eine erfolgreiche LIGNA 2019 ist beendet. Nach dem erfolgreichen Debüt vor zwei Jahren präsentierte HOLTEC erneut auf zwei Ständen ein deutlich…

Hirschbach vertraut bewährter Technik

Bei der Firma Hirschbach in Sulzbach-Laufen wurde im Jahr 2018 der Rundholzplatz um einen zweiten Sortierstrang erweitert.

Dritte Rundholz-Sortierlinie für Pinhoser/PT

Seit 28 Jahren betreibt Herr António Fernandes das Sägewerk PINHOSER mit angeschlossener Palettenfertigung in Serta, ca. 200 km nordöstlich von…

HOLTEC auf des Lesdrevmash in Moskau

Vom 22. bis 25.10.2018 beteiligte sich die Firma HOLTEC zum achten mal an der Lesdrevmash in Moskau, der 18. Internationalen Fachausstellung für die…

Montageabschluss bei Holzwerke Weinzierl

Anfang November konnte die Montage der wichtigsten Anlagenteile bei Holzwerke Weinzierl wie geplant abgeschlossen werden.

Inbetriebnahme bei Piveteau Bois in Sainte Florence

2018 lieferte die Firma HOLTEC einen Rundholzplatz an die Firma Piveteau Bois in Sainte Florence.

Maderas Vicente Castillo nimmt HOLTEC Paket Kappstation in Betrieb

Maderas Vicente Castillo e Hijos S.L. ist Spaniens größter Hersteller von EUREPAL Paletten mit Sitz in Soneja, Provinz Castellón

Investition in neue Sortierlinie

Um dem technischen Fortschritt gerecht zu werden, investierte man im Hochleistungssägewerk der Ziegler Group in Plößberg in eine neue Sortieranlage,.

Norbord nimmt neue OSB-Linie in Inverness in Betrieb

In den vergangenen Monaten wurde die Anlage bei Norbord in Inverness installiert und in Betrieb genommen.

Austausch Entrinder (Rotary Debarker) bei Kronospan S.A.

Eines der herausforderndsten Projekte in jüngster Zeit war der Austausch einer Entrindungsmaschine (Rotory Debarker) in einem Werk der…

Holzwerk Baumann nimmt modernen Rundholzplatz in Betrieb

Auf dem neuen Rundholzplatz kann Langholz bis 21m Länge und Durchmesser von 10 bis 90cm, sowie Abschnitte bis 14m länge verarbeitet werden.

HOLTEC erhält Auftrag über neue Rundholzsortierung bei Holzwerke Weinzierl

Die Holzwerke Weinzierl betreiben in Vilshofen / Bayern eines der leistungsfähigsten Nadelholzsägewerke Deutschlands.

Neues Highlight in Russland – Holzplatz-Auftrag von Pavlovskiy DOK

Unser langjähriger Kunden ALTAILES betreibt in der Altai-Region bereits mehrere Sägewerke mit einem Einschnittvolumen von > 1,5 Mio. Festmeter…

HOLTECs erfolgreicher Messeauftritt in Hannover geht zu Ende

Vom 22.-26. Mai 2017 präsentierte sich HOLTEC auf der LIGNA, der Weltleitmesse für Maschinen, Anlagen und Werkzeuge zur Holzbe- und verarbeitung in…

25-jähriges Firmenjubiläum in HOLTEC Niederlassung OST gefeiert

Anfang Januar 2017 feierte die Firma HOLTEC das 25-jährige Betriebsjubiläum der Niederlassung OST.

Erfolgreiche Ersatzinvestition bei Ante-Holz in Somplar

Die Fa. Ante-Holz GmbH in Somplar hat zum Ende des vergangenen Jahres die Investitionsentscheidung für den Austausch einer Auswerfereinheit und…

HOLTEC erhält Auftrag von FOREST SAWMILL

Integration eines Reduzier-Bypasses bei Großbritanniens größtem auf Zäune spezialisierten Sägewerk„Hergestellt in Großbritannien mit Holz aus…

Großauftrag der KRONOSPAN-Gruppe für OSB-Holzplatz in Russland

Ende letzten Jahres erhielt HOLTEC einen weiteren Großauftrag von KRONOSPAN für einen Holzplatz in Russland.

Stallinger in Frankenmarkt (A) tauscht den Sortierblockzug aus

Bei der notwendigen Ersatzinvestition im Bereich des Sortierblockzug fiel die Wahl auf HOLTEC. Nachdem bereits 2003 ein Beschleunigungsrollengang von…

Großauftrag von NORBORD für OSB-Neubau in Inverness

Norbord modernisiert und erweitert das OSB-Werk in Inverness, UK. Hierzu verlagert das Unternehmen die bestehende kontinuierliche DIEFFENBACHER Presse…

Egger produziert in neuem MDF Werk Gagarin/Rus erste Platte

HOLTEC liefert ersten, 3 rotorigen Variobarker

Hackschnitzelproduktion für Pellets in der Bretagne

Inbetriebnahme des Holzplatzes abgeschlossen

Unser Versprechen

Tradition, Verantwortung, Wertschätzung

Wir tun mehr für unsere Kunden, Mitarbeiter, Partner. Das ist die Basis unserer täglichen Arbeit. Wir entwickeln Produkte, die wirklichen Kundennutzen bringen und stehen mit unserem Namen für Service und Qualität.

Eine Unternehmenskultur mit offenen Türen, ein fairer Umgang mit unseren Mitarbeitern und Partnern und die tägliche Motivation und Faszination für unsere Arbeit zeichnen uns aus.

Die beste Lösung – das ist unser Anspruch. Und unser Versprechen.